Plan created by Trainboard member @gary60s The download ZIP contains the full plans, images and templates.

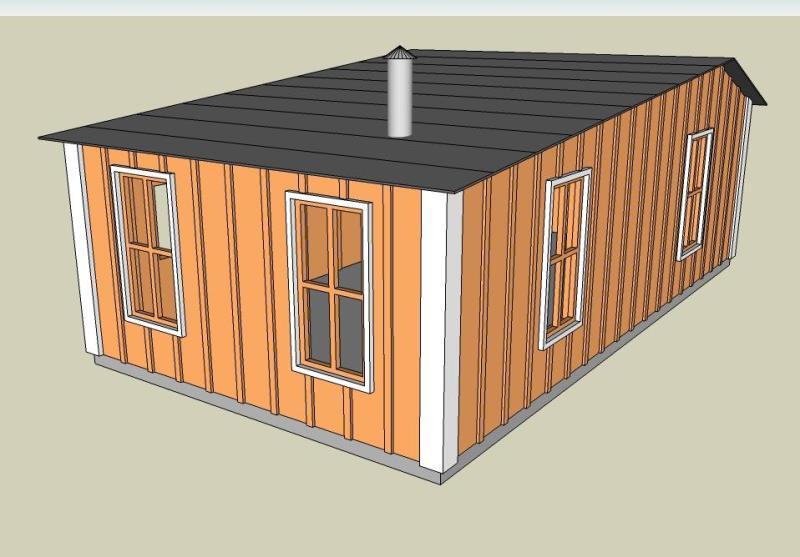

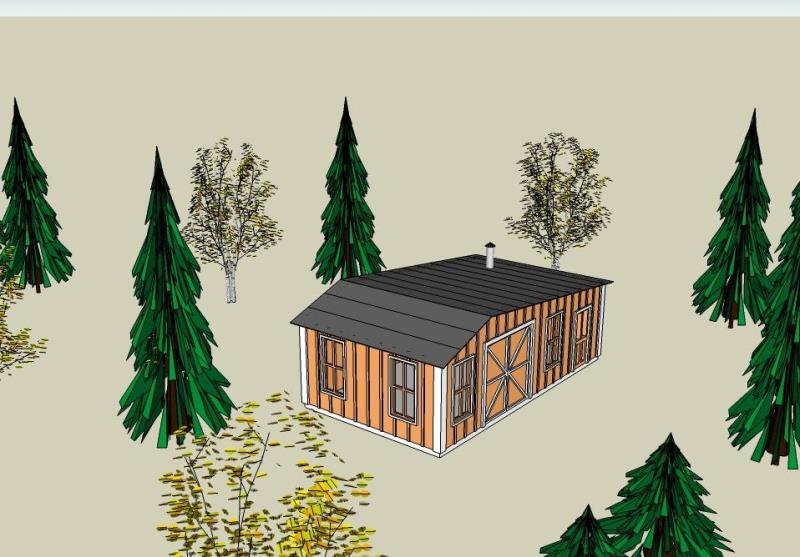

We all know what Wooty does for a living. When he's not busy being a smiley, he runs Wooty's bar and grill. In his spare time, Wooty has always been a shade tree mechanic, but when his bar did so well (standing room only Wednesday wet T shirt contests, and Friday happy hours), he decided to move up and trade the shade trees for a nice shop. Here is a sketch set of "Wooty's Workshop", so you can scratch your own.

Footprint is 1 1/4 x 2 1/4, it's an easy build, and can go anywhere on your layout. It can be done in wood but sketches are based on styrene thicknesses. If you use another material adjust dimensions accordingly. Paint parts before assembly, except where the edges glue to other parts.

The building directions and materials are in the sketches, and to make your build easier you can enlarge them to full size and print them out. Read directions in assembly sketches before cutting out parts as you may want to change some sizes or cut fewer, or additional, openings. Included sketches are: Overview sketches, Parts templates, Assembly sketches, and PDF's.

To print the part templates actual size, use the PDF's. Select best printer quality, set PDF zoom to 100%, and page scaling to "none" or actual size. Check your printed page to see that 3" lines are exactly 3" long. Once you have template printed, you can cut with scissors (leave a 1/8" border) and arrange on your material for maximum sheet usage. Part templates for siding are a mirror image, when needed, so that you can cut walls with siding side down (easier to cut). Be sure siding grooves are oriented correctly. Use rubber cement or Krylon Easy Tack Repositionable Adhesive to glue paper templates to your material and then just cut on lines. No measuring ! Paper comes off easily.

Cut out parts carefully using a SERB and straight edge. The best way to cut out window openings is with a corner punch. It is important to follow assembly sketches IN SEQUENCE or some parts may not fit.

Most of my structures use a .040 thick base and should have ground cover around them (to hide the base) even with the bottom of the walls. An easy way to do this is by using "footprint boards".

N Scale Wooty's Workshop 2015-10-21

A small workshop detached from the house

Tags: